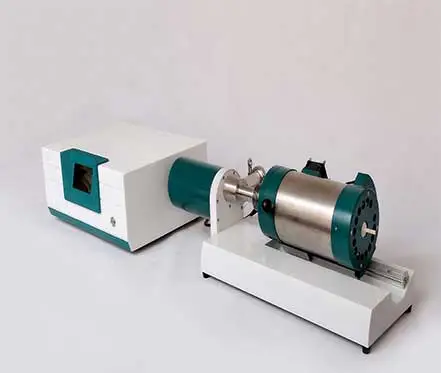

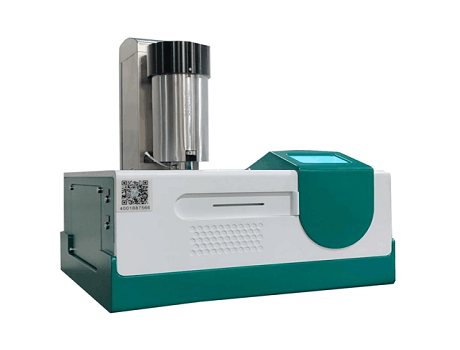

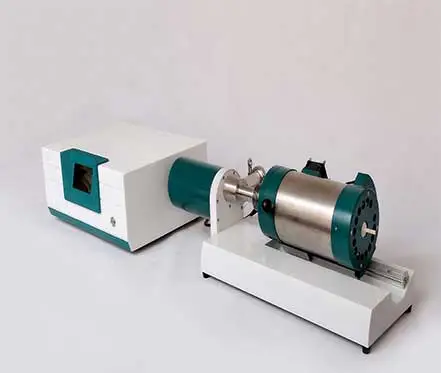

The horizontal dilatometer is a vital tool for measuring the dimensional changes of materials under varying temperature conditions. It plays a significant role in numerous industries that require precise analysis of thermal expansion, shrinkage, and other dimensional transformations. Whether in research and development or quality control, the horizontal dilatometer provides valuable insights into how materials behave under heat stress, which is critical for product development, material testing, and process optimization. Below are the primary applications of the horizontal dilatometer.

Materials Science: Understanding Thermal Expansion

In the field of materials science, the horizontal dilatometer is essential for understanding the thermal behavior of various substances. Accurate measurement of thermal expansion allows researchers to analyze the stability and performance of materials under temperature variations. The ability to assess these properties helps in developing materials with optimized thermal stability, which is vital for applications where temperature fluctuations are common.

Ceramics and Glass Industry: Sintering and Shrinkage Analysis

The horizontal dilatometer is also widely used in the ceramics and glass industry. These industries rely on the ability to monitor the dimensional changes during sintering and firing processes. By using the horizontal dilatometer, manufacturers can track how ceramics and glass materials expand or contract at specific temperatures, which helps in controlling the sintering process and achieving the desired product characteristics.

Metallurgy: Evaluating Thermal Stress and Phase Transitions

In metallurgy, understanding the thermal expansion properties of metals and alloys is critical for designing materials used in high-temperature environments. The horizontal dilatometer is instrumental in measuring the thermal expansion of metals under controlled heating conditions. It provides critical data about how metals expand during heating and contract during cooling, which directly influences their ability to withstand thermal stresses during manufacturing and operation.

Aerospace and Automotive Industry: High-Temperature Performance Testing

The aerospace and automotive industries demand materials that can maintain their structural integrity at high temperatures. The horizontal dilatometer is used to test the high-temperature performance of materials, ensuring that components such as turbine blades, exhaust systems, and engine parts remain dimensionally stable under heat stress. This testing ensures the safety, durability, and performance of critical components.

By measuring thermal expansion, manufacturers can optimize the design and selection of materials that can withstand the extreme conditions encountered in aerospace and automotive applications. The horizontal dilatometer plays a crucial role in reducing the risk of material failure in high-temperature environments.

| Feature | Benefit | Application Example |

|---|

| High Temperature Measurement | Accurate testing up to 1600°C or higher | Ceramics, metal alloys |

| Real-Time Monitoring | Continuous data collection during testing | Aerospace components, automotive testing |

| Precision Sensors | Accurate measurement of small dimensional changes | Material R&D, high-precision manufacturing |

| User-Friendly Interface | Easy setup and control with advanced software | Laboratories, industrial quality control |

In conclusion, the horizontal dilatometer is a versatile and essential tool for various industries requiring precise thermal expansion and dimensional change measurements. From materials science to metallurgy and aerospace applications, it ensures that the materials used in critical environments meet performance standards and safety requirements. Whether for research or manufacturing, the horizontal dilatometer provides accurate data that helps improve product development, quality control, and material performance.

For all your horizontal dilatometer needs, HENVEN provides high-quality, reliable instruments designed to meet the demands of modern research and industrial applications.

English

English 한국어

한국어 Deutsch

Deutsch русский

русский العربية

العربية Türkçe

Türkçe