The TGA machine and DSC analysis machine are two important thermal analysis techniques widely used in fields such as material science, chemical engineering, and pharmaceuticals. However, they focus on different aspects and provide distinct types of information.

What is the Difference Between TGA and DSC?

Principle

TGA Machine: The TGA machine analyzes materials by measuring the change in mass of a sample as a function of temperature under controlled conditions. The sample is placed in a heating furnace, where the temperature is gradually increased according to a predefined program, and the mass reduction of the sample is monitored in real-time.

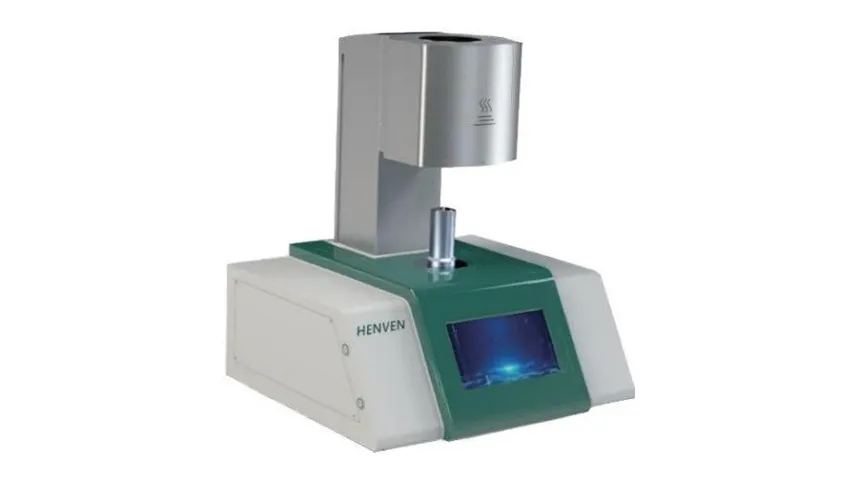

DSC Analysis Machine: The DSC analysis machine measures the thermal effects of a sample by comparing the energy difference between the sample and a reference material. When the sample undergoes endothermic or exothermic processes (such as melting, crystallization, glass transition, etc.), the instrument detects the flow of energy into or out of the sample, reflecting its thermodynamic properties.

Applications

TGA Machine: TGA is primarily used to evaluate the thermal stability, decomposition processes, moisture and volatile content, redox reactions, the impact of additives and fillers, and reaction kinetics of materials. TGA provides information on sample weight loss, helping to determine decomposition temperatures, weight loss percentages, and more.

DSC Analysis Machine: DSC is used to measure properties such as the glass transition temperature, melting point, crystallinity, phase change enthalpy, specific heat capacity, oxidation induction time, and decomposition temperature. DSC is particularly useful for understanding the thermal behavior of materials, especially phenomena related to energy conversion.

Type of Information

TGA Machine: The TGA machine provides a relationship between mass change and temperature but does not directly show energy changes.

DSC Analysis Machine: The DSC analysis machine reflects the relationship between heat flow or energy changes and temperature but does not directly indicate mass changes.

Summary

The TGA machine focuses on understanding the physical and chemical changes of a sample during heating through mass change, such as thermal stability and weight loss. In contrast, the DSC analysis machine analyzes the thermodynamic properties of a sample by measuring energy changes, such as phase transitions and melting points. Using both techniques together offers a more comprehensive thermal performance analysis of materials.

English

English 한국어

한국어 Deutsch

Deutsch русский

русский العربية

العربية Türkçe

Türkçe