-

Products

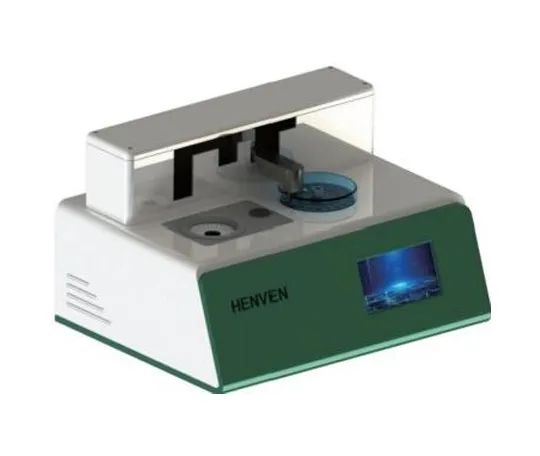

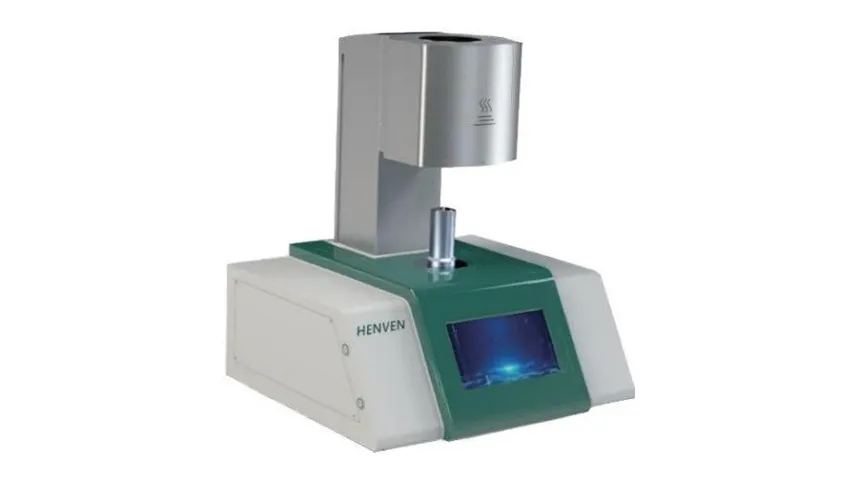

Large Scale TGA High Pressure TGA STA (Synchronous Thermal Analyzer) DSC (Differential Scanning Calorimete) TGA (Thermogravimetric Analyzer) Customized Thermogravimetric Analyzer DIL (Dilatometer) TMA/DMA DTA (Differential Thermal Analyzer) Calorimeter Thermophysical Property Tester X. Optional Accessories

- Applications

- Company

- Services

- Resources

- News

- Contact Us

English

English 한국어

한국어 Deutsch

Deutsch русский

русский العربية

العربية Türkçe

Türkçe