Instrument Parameter of HCJ-1 Thermal Shock Test Device

In this device, both the high-temperature furnace and the low-temperature furnace are heated by silicon carbide tubes. The two furnaces can realize continuous temperature rise adjustment from room temperature to 1400℃ and can maintain a constant temperature at any point.

High-Temperature Furnace (High-Temperature Zone Of Thermal Shock Test) |

Heater Material | Silicon Carbide Tube Element |

Maximum Operating Temperature | 1400℃ |

Temperature Control Accuracy | Better Than ±0.5℃ |

Length Of Constant Temperature Zone | 90mm |

Inner Diameter Of Furnace Chamber | 50mm |

Maximum Allowable Error Of Thermocouple | ±0.25%t |

Distance From Thermocouple Measuring End To Sample | Less Than 8mm |

Maximum Heating Rate | 40C/min |

Temperature Field Uniformity In Constant Temperature Zone | ≤±2℃ |

Temperature Rise Of Furnace Wall Surface | ≤45℃ |

Vacuum Unit | Vacuum degree ≤ 10Pa, pumping speed 4L/s, vacuum gauge accuracy: relative indication error 3% |

Gas Circuit Unit | This unit is equipped with a 3-channel gas mass flow controller, enabling continuous adjustment of gas flow rates for 3 gas paths with a range of (0~100) ml/min. The 3-channel mass flow controller is suitable for inert protective atmospheres such as N₂, Ar, and He. It is also equipped with solenoid valves, allowing automatic switching between the 3 gas paths. |

control system |

It can control the heat output voltage of the high-temperature furnace and low-temperature furnace according to the feedback signal from the temperature controller, thereby realizing temperature control inside the furnaces. |

It can automatically set the type of reaction gas and control the gas flow rate by controlling the 3-channel mass flow meter, solenoid valve, etc. |

It can automatically evacuate and display the vacuum degree inside the furnace in real-time. |

It can control the transfer mechanism to automatically transfer between the high-temperature furnace and the low-temperature furnace, or between the high-temperature furnace and the circulating water tank. |

Experimental procedures can be set, including parameters such as vacuum evacuation, vacuum degree setting, protective atmosphere type, gas flow rate, experimental temperatures of high and low temperature zones, constant temperature time, and number of thermal shock test cycles. Once the program is set, the system can operate automatically without manual intervention. |

Interlock protection: It is equipped with interlock protection functions against over-temperature, over-current, misoperation, etc., which can produce an interlocking effect with the heating unit. This ensures that when the equipment encounters unexpected situations, timely protection can be provided for hardware or software. |

Operation alarm: When the heating unit, vacuum unit, or gas circuit unit malfunctions, an automatic alarm will be triggered. The alarm adopts an audible and visual alarm mode, and can be cleared through the configuration software or the buttons on the control cabinet. |

Constant Temperature Circulating Water Tank |

Temperature Range | -20~100℃, the circulating water tank is equipped with both heating and cooling functions, and can maintain a constant water temperature at any point within the range of -20~100℃. |

Temperature Control Accuracy | Better than 0.1℃ |

Water Tank Capacity | 20L |

Water Tank Material | 304 stainless steel, with insulation materials to be added in the interlayer. The total thickness of the inner wall, outer wall and insulation layer shall be ≥ 30mm. |

The temperature difference between the inlet water temperature and outlet water temperature during the sample quenching process: ≤ 5℃ |

It has heating and refrigeration functions. Through setting, it can automatically track and adjust the temperature of the circulating water, with adjustable outlet flow rate. Meanwhile, it is equipped with low liquid level and over-temperature alarm as well as protection functions. |

Sample Clamping And Transfer Mechanism |

It consists of a central rod and sample fixtures, enabling the clamping and automatic transfer of samples with different shapes and sizes. |

No mechanical collision will occur during the sample transfer process, which could otherwise cause sample damage. |

The sample can be automatically and rapidly switched among the high-temperature furnace, low-temperature furnace, and circulating water tank. The switching time is controllable and less than 2s. |

sample specifications |

Material | Any material can be used as long as it can withstand temperatures below 1400℃ |

Shape and Size | Any sample of any shape is acceptable as long as its length, width, and height are all within 30mm |

Thermal Analysis Accessories of HCJ-1 Thermal Shock Test Device

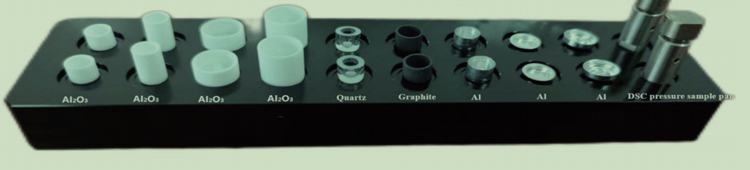

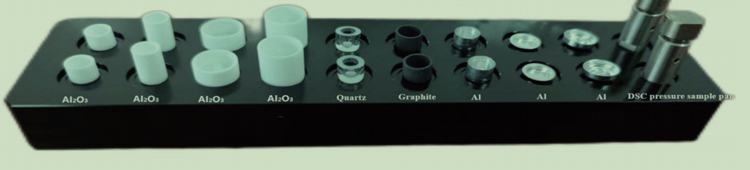

Beijing HENVEN provides various crucibles such as alumina, zirconia, graphite, quartz, aluminum, platinum, and stainless steel, which can meet almost all material testing and application needs.

Different measurement modes, different temperature ranges, different sample morphologies..

The instrument can be equipped with conventional brackets, corrosion-resistant brackets, and high-sensitivity brackets, which are suitable for different sample conditions and testing requirements.

Constant temperature control system , including constant temperature gas chromatography, mass spectrometry, and infrared spectroscopy connectors; constant temperature zones.

It has excellent expandability and can be coupled with Fourier Transform Infrared Spectrometer (FTIR), Mass Spectrometer (MS), and Gas Chromatograph (GC) to complete secondary detection of gas products from thermal analysis experiments. Temperature range: room temperature ~ 200℃, temperature control accuracy: ±0.1℃.

DSC optional accessories

UV curing system: It can realize the curve measurement of rapid curing of monomer and multimer solutions under irradiation of light with a certain intensity.

English

English 한국어

한국어 Deutsch

Deutsch русский

русский العربية

العربية Türkçe

Türkçe